DIGITAL TWIN TECHNOLOGIES FOR METAL CASTING ENTERPRISE

Understanding Foundry Resource Planning (FRP®) in metal casting operations

The Covid-19 pandemic is THE major disruption since WW2, let’s face it!!

Physical lockdowns are causing the loss of visibility to the entire supply chain.

From front to back and all the way down to the very end of prospectus client’s enquiries.

You simply are unable to track data due to unavailability of functional integrated digital platforms and to know at the same time what is where.

The NEW NORMAL is a metal casting business enterprise that is designed with digitalization in mind right from start !! Let’s make our industry a respectable one and change our image from 3D (dirty – dangerous – difficult) to D3 (digital – dynamic – different)

One quintessential step for the above is to have a digital strategy supporting your operations

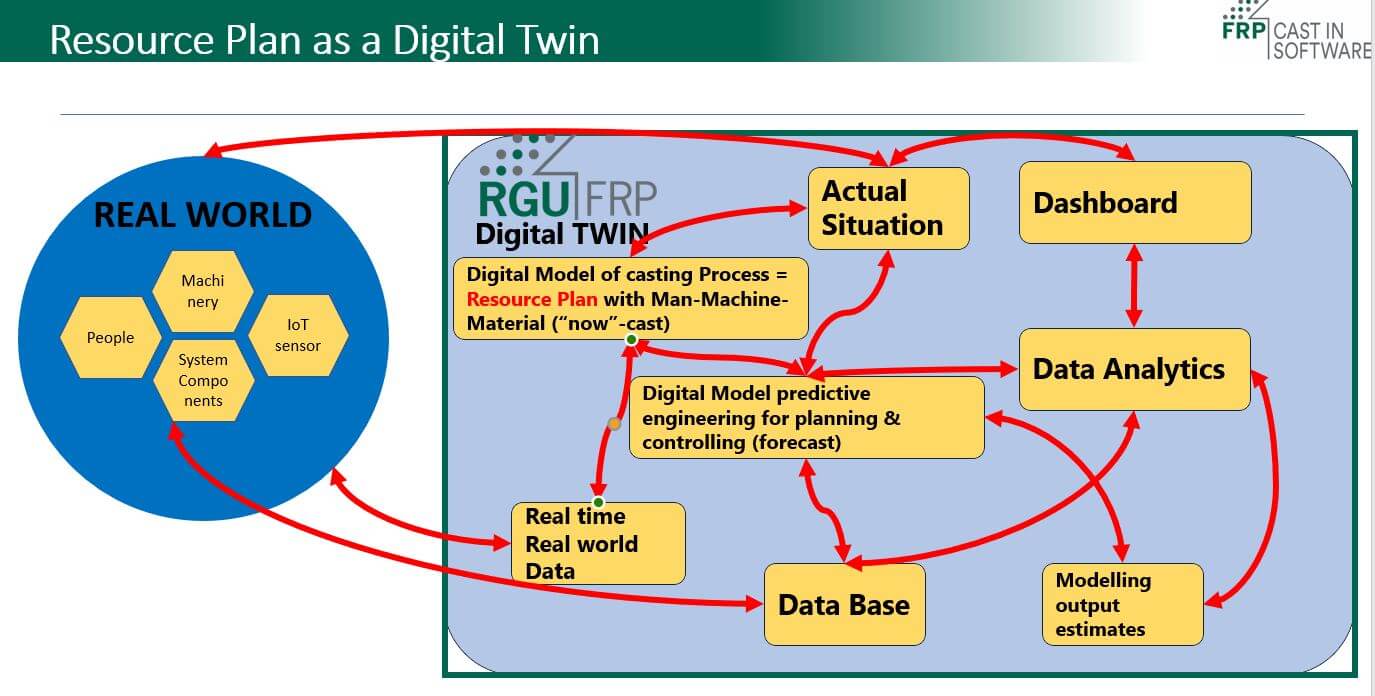

FRP® – Foundry Resource Planning solutions has at its core a “RESOURCE PLAN” = (RP) made of man-machine-material requirements

- The RP is simplified expressed a “digital twin” of the manufacturing process of how to make a casting from scratch and considering all process steps until dispatch

- The RP goes WAY beyond BOM and integrates Material – Machine – Cycle time (Man Power) – Formula of items – Costing – Setting time – etc. for all the stages of the foundry from melt to finished part

- The RP is the “Backbone” of the FRP® software and is used for ALL activities in PPC and ALL queries in regards to delivery reliability / purchase / quality / etc. will fall back on it

- The RP has further functions in predictive maintenance and data analytics and allows to digitally compare PLAN with ACTUAL in REAL TIME

- The RP technology has even to a certain extend AI (artificial intelligence) incorporated since it allows to support future activities to forecast based on present data.

For further details check this out : here…